A Ball Check Valve is a simple and reliable valve with the only moving part to block the reverse flow is a spherical ball. Floating Ball Valve 3-Way Structure Flanged end.

Metal-seated valves that maintain tight shut-off and valves designed to maintain the performance of your processes from elevated temperatures to.

. Body to Stem anti-static Ball Ball to Stem anti-static Ball PTFE gasket Primary Seal Graphite gasket Secondary Seal Spiral wound gasket. Floating Ball Valve - Design Features. Our offshore experience also enables us to.

There are soft seated designs that provide superior sealing. Though they tend to be larger there are smaller sized three-piece floating ball valves designed for use in compact situations. Ball valve design in which the ball is not rigidly held on its rotational axis is free to float between the seat rings.

An advantage of trunnion ball design over floating ball is the lower operating torque of the ball. In the closed position ball is pushed against the seat by the pressure of the fluid from upstream and hence can pressure seal the downstream of the valve. Two pieces design generally is used for sizes DN 10 38 to DN 125 5 Three pieces design generally is used for sizes DN 150 6 to DN 250 10.

Free Shipping Over 99. The three-piece floating ball valve refers to a floating ball valve whose body is composed of three parts from left to right. Contromatics Flanged Floating Ball Valves are a prime example of reliability performance manufacturing and superior engineering techniques at work.

Flomatic Corporation is a ball valve ball check valves floating ball valve and unleaded ball valve manufacturers and global distributer. Featuring a unibody or two-piece bolted design. At the design stage all projects are analysed using 3D solid modelling tools.

This 3-way flanged ball valve from Kinvalve is available in stainless steel and carbon steel. We are able to manufacture floating ball valves to complex project specifications on a fast track basis due to our smart sealing design. Metal to Metal Fire-Safe Seal After RTFE Melt down Metal to Metal Fire-Safe.

Size ClassConfiguration in 150 300 12 RP n n 34 RP n n 1 RP 4 FPn n 1 FP 6 RPs 112 RP n n. Trunnion mounting is used on larger valves as it can reduce the operating. Ad Huge Selection of Nipples and Valves In Stock.

Our Floating Ball Valves are available in an ex - tensive range of designs materials sizes and pressure classes and are in full conformance with ANSI API and NACE specifications. The parts are usually a body and two bonnet. Size Range Design Availability P O A.

Floating Ball Valve Design. Designs of ball valves designs of ball valves --the floating ball design the floating ball design which relies on the valvewhich relies on the valve seats to seats to support the ball and the trunnion mounted ball which uses a trunnion to support the ball. Before we dive into the details of floating ball valve design lets define the key components of a ball valve.

FLOATING BALL VALVES APPLICATIONS Floating ball design Blow-out proof stem desing Face to face to per ANSI B1610 Flange dimensions to per ASME B165 Shell wall thickness to per ASME B1634 Valve design to per API 6D Split body to per BS 5351 Sour service to per NACE MR-0175 Mounting pad to per ISO 5211. In this post well cover the details of floating ball valve design and its applications as well as the situations in which you might choose trunnion-mounted over floating. Obviously this difference becomes.

Mounting and Stem Seal Design Fire Safe Design Anti-Static Design Unibody Ball Valve Design. All ball valves are designed in accordance with ASME B1634 and where applicable with API 6D or BS EN ISO 17292. This is particularly advantageous when the ball valve is actuated because it reduce the size of the actuator and hence the overall costs of the valve actuation package.

The key to ball valve performance is the sealing design regardless of whether the seats are made of metal plastic or other material. The FBC is a compact lightweight insert wafer check valve that easily installs between two flanges. Ad Standard Custom Automated Ball Valve Design Support from Our US Facility.

It comes in different sizes or between 12 12. BFE Floating Ball Valve design is developed using the latest software based analysis tools. The handle lies flat aligning with the flow when open and perpendicular when closed.

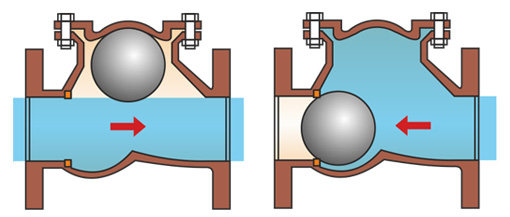

A ball valve ball check valve is open when the balls hole is in line with the flow and closed when pivoted 90-degrees by the valve handle. Our floating ball valve is designed for excellent sealing performance and longevity. The in-line spring assisted design prevents water hammer and reverse flow.

Similar to the case of two-piece floating ball valves the end caps are usually connected through threads and bolts by welding them or flanged to the pipe. For vacuum or anti-flooding valve application a floating rather than sinking ball is used. Ball valves with floating ball design have split body and can be provided depending on the pressure class in sizes from DN 10 38 to DN 250 10.

Larger sizes upon request. The full-ported valve seat is uniquely designed allowing the ball to seat leak-tight without getting wedge into the valve seat. The FBC contains all of the proven features of the Basic-Check valve developed by DFT Agency Standard.

Benefi ts include reduction of development time and cost improved product quality and ability to solve fi eld problems for customers. The BFE family of floating ball valves provides positive shut-off of fluids and gases. Ad A variety of adjustable check valves to meet your system needs.

Ball seats on the downstream seat only. Gemini Valve Has 50 Years of Manufacturing Expertise. Three-piece floating ball valves have three pieces of housing and are the most expensive subtype.

A floating ball valve is a ball valve with an unsupported ball other than the two seats it rests on so that the ball moves in the valve cavity to help seal off the line pressure. Reliable valves to control back flow in a variety of applications. The floating ball valve portfolio includes a diverse range of standard and customized valves that can be configured to suit most process applications or project packages.

These sections are forged to each other with one half of the body being larger and housing all the moving valve parts. It is available in L or T port configurations comes with a full-port design and dismountable end connection pieces. Valve body the chamber in which the valve mechanism is encased.

Similarly trunnion mounted ball design is also capable of bi-directional sealing.

Ball Check Valve Learn About The Features And How To Install Avk Youtube

Introduction To Check Valves The Process Piping

China Customized Float Ball Flange Check Valve Manufacturers Suppliers Factory Direct Wholesale Anwvf

China Pfa Lined Check Valve Floating Ball Check Valve China Floating Ball Check Valve Flanged Check Valve

Ball Type Check Valves Normex Check Valves Manufacturer India

What Are Check Valves Types Working And Symbols Of Check Valves With Pdf What Is Piping

0 comments

Post a Comment